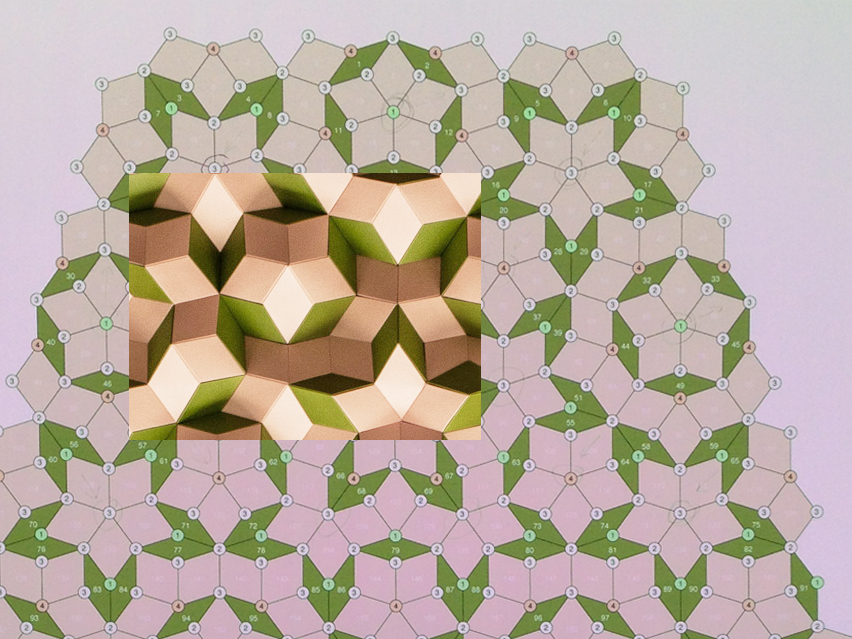

I am feeling a little giddy because I just won an award for the first mathematical artwork I’ve ever exhibited. “Laura’s Flowerpot” is a collaborative work made with my friend Duane Bailey, a mathematician and professor of computer science at Williams College, Massachusetts. The exhibition was curated by the Bridges Organization for the 2021 Joint Mathematics Meetings, an international conference of mathematicians. You may visit the exhibition here, and watch a 9min video of Duane and I discussing our sculptures.

The Artist Reception is today, Friday Jan 8th by zoom. All are welcome. Time: 4pm EST, 9pm GMT Information on how to attend the reception is below.

Join the Zoom reception via your web browser, the meeting ID is 867 8631 2058, and the Passcode is JMMbridges. If accessing by phone, the Passcode is 7707585650. Find your local number here. There will be Zoom breakout rooms so that small groups can split off to discuss particular topics in more depth. To access these you must have version 5.3 or later of the Zoom app. Please upgrade before the meeting if needed, at zoom.us.

Happy New Year indeed! I’m looking forward to connecting with old friends and meeting some new ones.

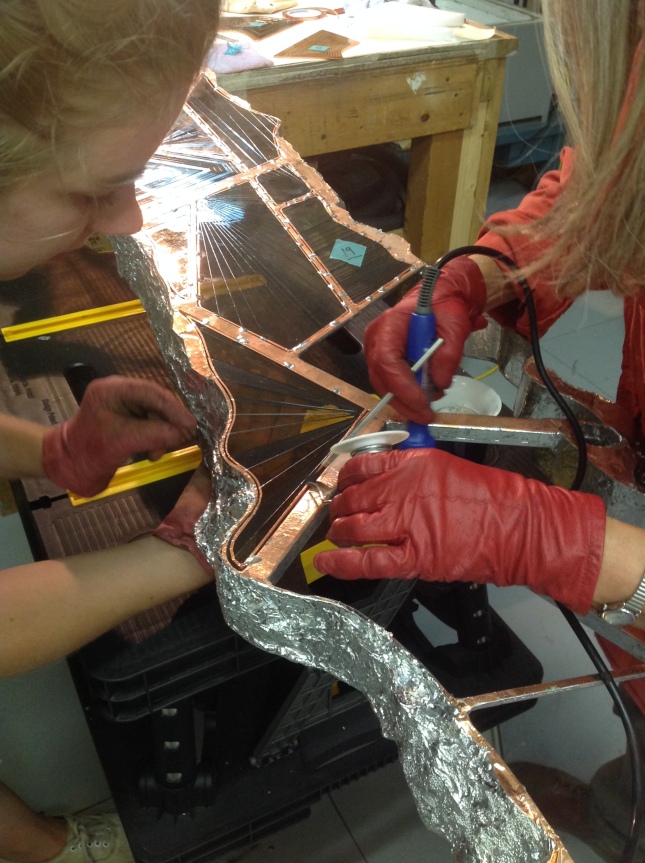

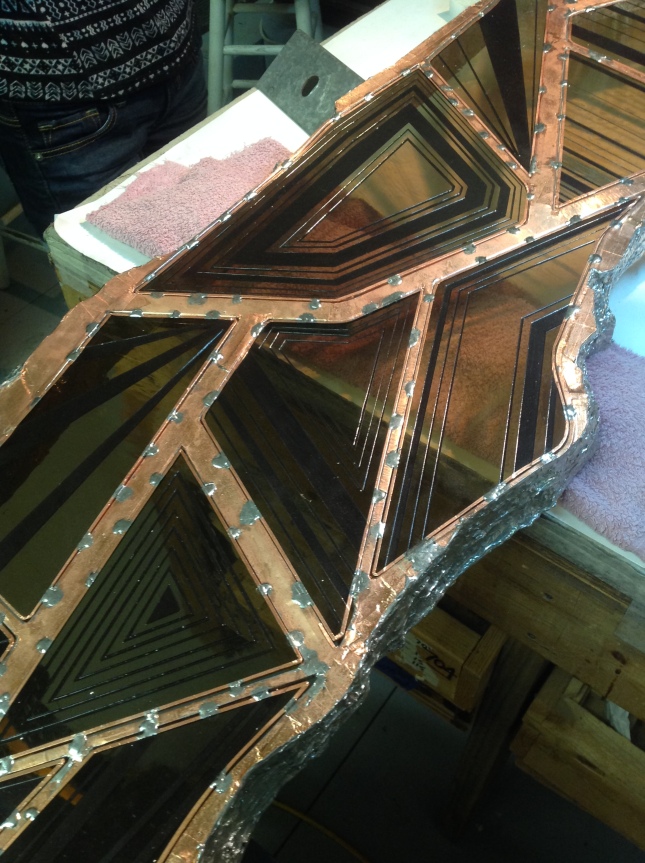

The glass on the left still has one layer of contact paper from the sandblasting. I’m painting enamel into the areas that were blasted.

The glass on the left still has one layer of contact paper from the sandblasting. I’m painting enamel into the areas that were blasted.